High-Strength Aircraft Aluminum Plate for Key Aircraft Parts

Aircraft aluminum sheet is mostly used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear pillars, as well as rocket forging rings, spacecraft wall panels.

7475 T7351 Aircraft aluminum Plate is a high-strength, high-hardness aviation-specific aluminum material. It is mainly used to manufacture key parts such as aircraft frames, skins, and landing gears.

7475 T7351 Aircraft aluminum Plate has good corrosion resistance, high fatigue resistance and good plastic toughness, and can maintain good performance under extreme temperature and pressure conditions.

7475-T7351 Aircraft aluminum plate is an American deformed aluminum alloy plate suitable for plate and plate applications requiring high strength, excellent fracture toughness and resistance to fatigue crack propagation.

Typical fracture toughness values for Alloy 7475 plate are approximately 40% higher than Alloy 7075 in the same condition. The durability and fatigue properties of Alloy 7475 are equal to and in some cases better than many current high-strength aerospace alloys such as 7075, 7050 and 2024.

Product specifications

There are many specifications for aircraft aluminum plates, as follows

Aluminum sheet specifications

Thickness: 0.1mm~10mm

Size: 1000mm×2000mm; 1220mm×1440mm~1500mm×4500mm.

Aluminum plate specifications

Thickness: 10mm to 450mm, with the small plate size being 1000mm×2000mm and the large plate size being 1220mm×2400mm~1500mm~3000mm.

ASTM-B209 AMS4027N 6061-T651 Aircraft standard aluminum plate is mostly used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear pillars, as well as rocket forging rings, spacecraft wall panels.

parameter

|

Grade |

Temper |

Application |

|

2024 |

O,T351,T851 |

Fuselage structure, wing tensile component, shear web, stiff structure section |

|

2014 |

T851,T351 |

Fuselage machining component, bulkhead, wing skins and other structure component for high performance military aircraft |

|

2324 |

T39 |

Lower wing skins and wing box component for commercial aircraft |

|

7050 |

T7651,T7451 |

fuselage ring, frame |

|

7150 |

T6151,T7751 |

Upper wing skins for large commercial airplane which requires resistant to high pressure, upper wing reinforce plate and lower horizontal stabilizer panel for civil and military aircraft |

|

7055 |

T7751 |

Upper wing structure, horizontal stabilizer, keel beam, seat track, freight slide track |

|

7075 |

T651, T7651,O,T7351 |

Airplane structure component required high strength, moderate toughness and moderate corrosion resistance |

|

7475 |

T651,T7351 |

Fuselage skin, wing skin, wing spar, fuselage bulkhead |

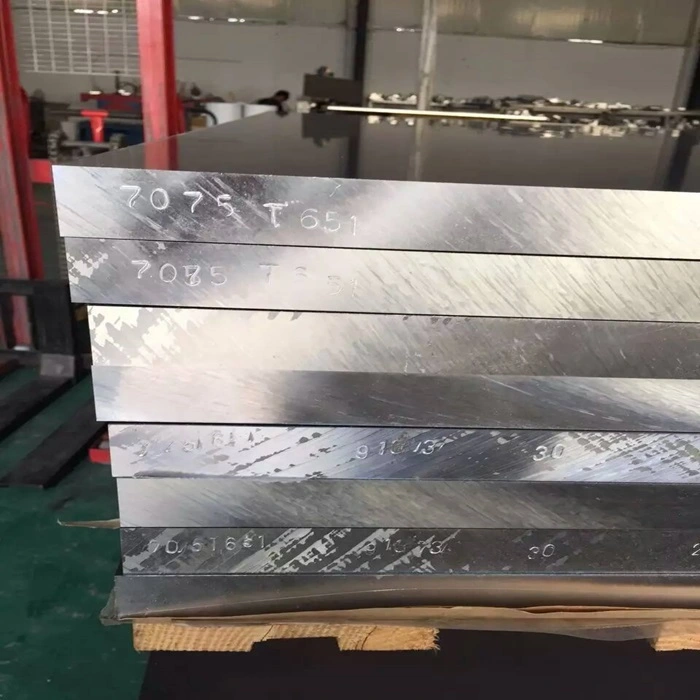

Product Display