Aluminum Perforated Metal Sheet for Exterior Facade Applications

An aluminum perforated sheet is a lightweight, versatile metal panel made from aluminum (or aluminum alloys) that has been mechanically punched, stamped, or laser-cut to create a precise pattern of holes. These holes can vary in size, shape, spacing, and arrangement, making the sheet adaptable to a wide range of functional and decorative applications

Composition & Properties

-

Material: Made from aluminum alloys (e.g., 3003, 5052), known for lightweight, corrosion resistance, and thermal conductivity.

-

Perforations: Holes created via punching, rotary pinning, or laser cutting, offering varied shapes (round, square, slotted) and patterns (staggered, straight, decorative).

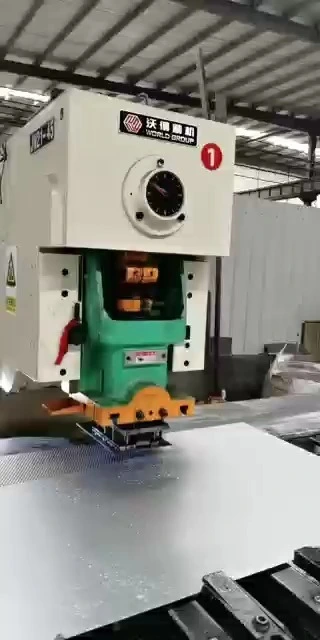

Manufacturing & Design Factors

-

Hole Specifications: Size (1mm to several cm), pattern, and open area percentage (30%–70%) impact functionality (airflow, filtration).

-

Thickness: Ranges from 0.5mm to 6mm, affecting strength and weight.

-

Finish Options: Powder-coated, anodized, or mill finish for aesthetics and durability.

Applications

-

Architectural: Decorative façades, sunshades, fencing.

-

Industrial: Filters, machinery guards, conveyor belts.

-

Automotive: Grilles, speaker covers.

-

Acoustic: Sound-dampening panels.

-

Consumer Products: Furniture, lighting, speaker grilles.

Advantages

-

Lightweight and easy to install.

-

Corrosion-resistant, ideal for outdoor use.

-

Customizable designs for aesthetic and functional needs.

-

Recyclable and low maintenance.

Disadvantages

-

Higher cost than steel (though cheaper than stainless steel).

-

Lower structural strength; requires thicker gauges for heavy loads.

-

Potential debris accumulation in holes, needing periodic cleaning

Product Information

parameter

|

Material |

High-grade Perforated Aluminum Sheets |

|

Thickness |

0.1mm~12mm |

|

Mesh Length |

1.8m~2.44m |

|

Mesh Width |

0.8m/1.22m |

|

Perforated area percent |

from 7% to 83% |

|

Hole Type |

Diamond, round, square, rectangular, triangle, hexagon, hexagonal, slotted, oval, club, cross, louver, etc. |

advantage

Product Display

application