Aluminum Perforated Sheet for Ventilation, Filters, Screens & Equipment

HVAC Air Diffuser Material Aluminum Perforated Plate

Perforated Aluminum Sheet

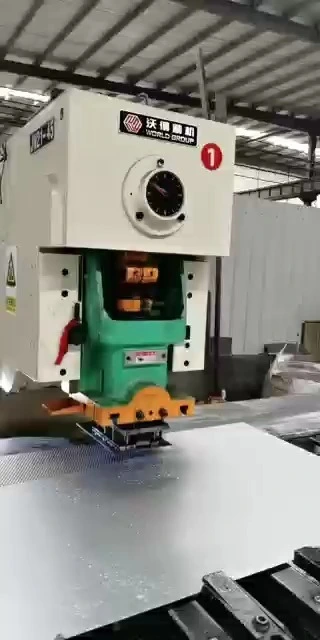

A perforated aluminum sheet is a type of metal sheet with an array of precisely punched holes. These holes can be of various shapes, such as round, square, hexagonal, etc., and are evenly or strategically distributed across the sheet.

Specifications

- Hole Diameter: Usually ranges from 0.5mm to 50mm, with common diameters like 1mm, 2mm, 3mm, 5mm, 8mm, etc. Smaller holes are often used for applications requiring fine filtration or a more delicate aesthetic, while larger holes are suitable for functions like ventilation with less air resistance.

- Hole Pattern: The most common patterns are straight - line (aligned in rows and columns), staggered (holes in adjacent rows are offset), and hexagonal (holes are arranged in a honeycomb - like pattern). The choice of pattern affects the strength, visual appearance, and functionality of the sheet.

- Sheet Thickness: Varies from 0.2mm to 6mm. Thinner sheets are more flexible and are often used in applications where light - weight materials are preferred, such as interior decoration. Thicker sheets offer higher strength and are suitable for more demanding structural or industrial applications.

- Size: Standard sheet sizes typically include 1000mm×2000mm, 1220mm×2440mm, but custom sizes can also be produced according to specific project requirements.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Information

1060 and 1050 perforated aluminum sheets are both common aluminum alloy perforated sheets. They have some similarities and differences in material properties, application areas, processing and installation.

The aluminum content of 1050 perforated aluminum plate reaches more than 99.5%, which is a kind of high-purity industrial pure aluminum.

The aluminum content of 1060 perforated aluminum plate is slightly higher than 1050, reaching 99.60%, which makes its material relatively softer.

Both have excellent electrical conductivity, thermal conductivity, corrosion resistance, and good plasticity and processing properties. However, due to the slightly higher aluminum content of 1060, its ductility and plasticity may be slightly better than 1050.

Applications

- Architectural Decoration: Used for building facades, ceilings, and interior partitions. The perforated design can add an interesting visual texture, and it can also serve as a functional element for light diffusion, ventilation, and sound absorption. For example, in modern - style office buildings, perforated aluminum sheets are often used on the exterior walls to create a unique and dynamic appearance while allowing natural light to penetrate in a diffused way.

- Industrial Filtration: Ideal for making filters in various industries. In the automotive industry, it can be used to filter air, oil, and fuel. In chemical plants, it helps filter liquid and gas mixtures. The precise hole size and pattern can be customized to meet different filtration requirements.

- Acoustic Applications: Since the perforations can trap and absorb sound waves, perforated aluminum sheets are widely used in sound - absorbing panels. They are installed in concert halls, theaters, and recording studios to improve the acoustic environment by reducing echo and noise.

- HVAC Systems: In heating, ventilation, and air - conditioning systems, perforated aluminum sheets are used as air diffusers and grilles. They can evenly distribute the airflow, ensuring efficient and comfortable air circulation in buildings.

parameter

|

Material |

High-grade Perforated Aluminum Sheets |

|

Thickness |

0.1mm~12mm |

|

Mesh Length |

1.8m~2.44m |

|

Mesh Width |

0.8m/1.22m |

|

Perforated area percent |

from 7% to 83% |

|

Hole Type |

Diamond, round, square, rectangular, triangle, hexagon, hexagonal, slotted, oval, club, cross, louver, etc. |

advantage

Light material

The density of aluminum is relatively low, which makes the overall weight of perforated aluminum plate light, easy to transport and install.

High temperature and corrosion resistance

Aluminum alloy materials have good high temperature and corrosion resistance, suitable for a variety of harsh environments.

Non-flammable

Aluminum is a non-combustible material, which improves the safety of the building.

Good stability

After special treatment, the perforated aluminum plate has good dimensional stability and flatness.

Strong decorative effect

Through different hole designs and color matching, a variety of decorative effects can be achieved.

Product Display

sus304 stainless perforated sheet

Stainless-Steel-Perforated-Metal-Sheet

Perforated-aluminum-plate

perforated sheet

perforated plate part

application

Architectural decoration

used for indoor and outdoor architectural decoration, such as exterior wall decoration, ceilings, partition walls, stair handrails, etc. Through different hole designs, patterns, text or geometric figures can be formed to enhance the beauty and artistry of the building.

Ventilation and heat dissipation

Due to its good air permeability, perforated aluminum sheets can be used for the outer cover or grid of ventilation and heat dissipation equipment, such as coolers, fans, air conditioners, etc.

Filtration field

As a filter material, it is used to filter air, liquid or solid particles. By adjusting the pore size and hole shape, different filtering accuracy and effects can be achieved.

Acoustic sound insulation

It is used to make acoustic sound insulation materials such as sound-absorbing panels and sound insulation screens to effectively absorb and isolate sound waves, improve sound quality and reduce noise pollution.

Safety protection

used to make security windows, guardrails and other security protection equipment, which are transparent and meet safety requirements.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Useful Links

Products

Contact Us

Office Add: 4402 Building#4 Zhangjiang Hitech Park Xiaoxian Suzhou Anhui