5052 Aluminum Plate Manufacturer

5052 aluminum plate belongs to the AL-Mg series alloy aluminum plate. The main alloy element is magnesium, with a content between 2.2% and 2.8%. It also contains small amounts of manganese, chromium, beryllium, titanium and other elements. Among them, the main functions of manganese and chromium are to improve the alloy's resistance to stress corrosion cracking, increase the strength of the base metal and welds, and reduce the tendency of welding cracks.

5052 aluminum plate is stable against oxidation, corrosion and other chemical properties. It can maintain good performance for a long time in many corrosive media and is particularly resistant to atmospheric and seawater corrosion.

5052 aluminum plate has good adaptability to processes such as processing, riveting, deep drawing, welding and cutting, and can be processed into a variety of complex shapes.

Due to its excellent performance, 5052 aluminum plate is widely used in the following fields:

Ship manufacturing: 5052 aluminum plate has good corrosion resistance, so it is widely used in ship manufacturing and repair, especially in the marine environment, its corrosion resistance is fully reflected.

Automobile industry: 5052 aluminum plate has high strength and good plasticity, and can be used to manufacture body parts, doors, hoods and other components, helping to reduce the weight of cars and improve fuel efficiency.

Architectural decoration: 5052 aluminum plate has a smooth and beautiful surface and can be used to make curtain walls, ceilings, doors, windows and other components, giving buildings a more modern and beautiful appearance.

Electronic products: 5052 aluminum plate has good electrical conductivity and plasticity, and can be used to manufacture computer casings, mobile phone casings and other components.

Aerospace: 5052 aluminum plates are also used to manufacture aircraft fuel tanks and other components to meet the requirements of the aerospace field for lightweight, high-strength, and corrosion-resistant materials.

Available aluminum sheet grade

1000 series: 1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series: 2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series: 3003,3004,3102,3104,3105,3005, etc.

4000 series: 4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series: 6061,6063,6262,6101, etc

7000 series: 7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H: H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

5052 is an aluminium alloy, primarily alloyed with magnesium and chromium.

5052 aluminum is the highest strength alloy of the more non-heat-treatable grades. Its resistance to fatigue is better than most grades of aluminum.

Alloy 5052 has a good marine atmosphere corrosion resistance of saltwater and excellent workability.

5052 aluminum is popular because it is one of the most versatile aluminum alloys. It is strong enough for fuel tanks, but adaptable enough for utensils.

Aluminum 5052 has a smoother finish than 6061 Aluminum, although it is not heat-treatable.

Aluminum 5052 has a higher fatigue strength and modulus of elasticity than Aluminum 6061, making it an excellent forming alloy. Aluminum sheet 5052 is used in many types of industrial applications, including: Fuel tanks

parameter

|

Thickness |

0.2-6.0mm |

|

Width |

100-2400mm |

|

Length |

200-11000mm |

|

Mother coil |

CC or DC |

|

Weight |

About 2mt per pallet for general size |

|

MOQ |

5ton per size |

|

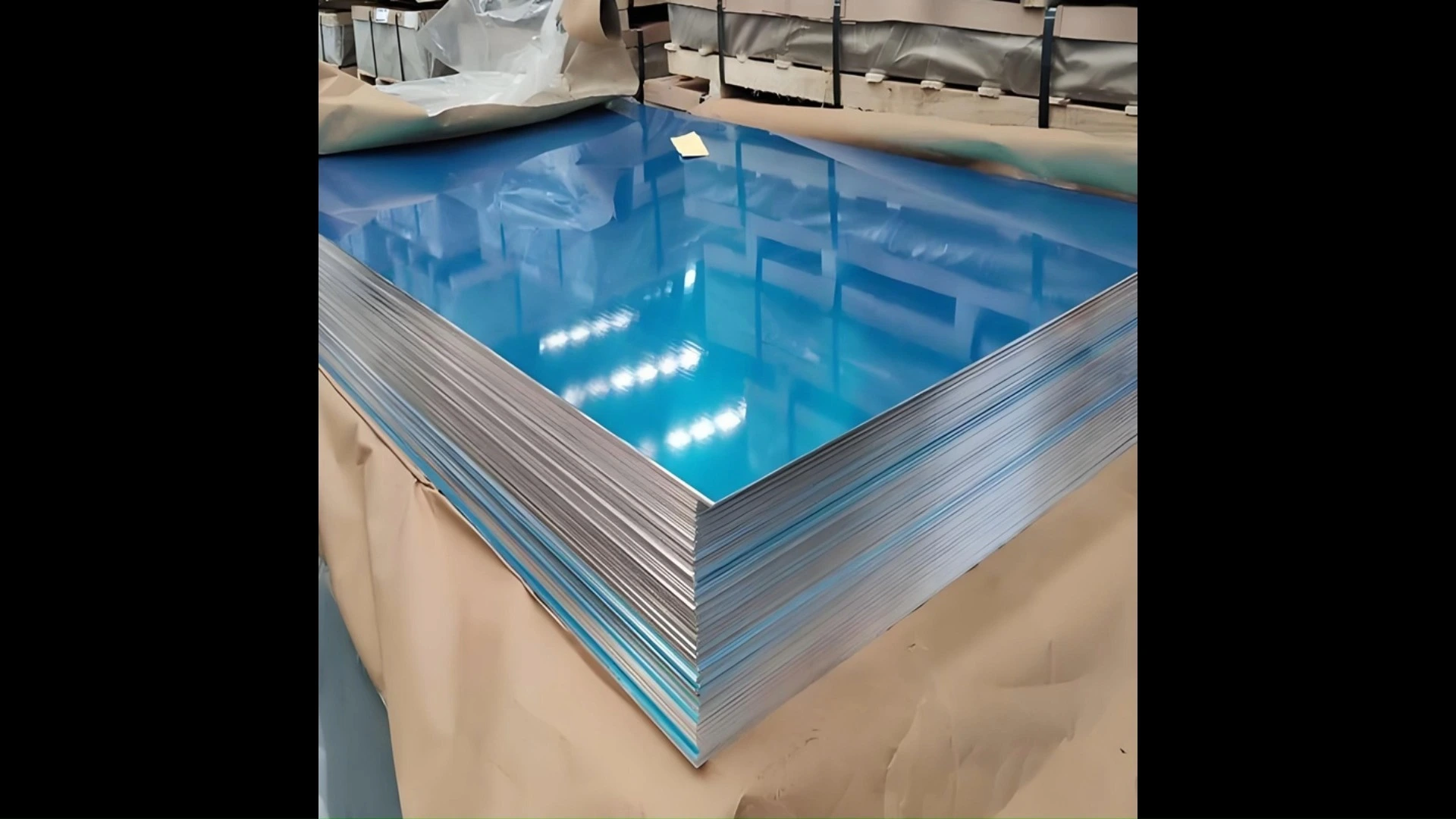

Protection |

paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement. |

|

Surface |

clean and smooth, no bright speck, corrosion, oil, slotted, etc. |

|

Standard product |

GBT3880, JIS4000, EN485, ASTM-B209 |

|

Delivery time |

about 30days after receiving the deposit |

|

Payment |

T/T, L/C at sight |

|

Trading terms |

FOB, CIF, CFR |

Application