5086 Aluminum Plate for Ship and Marine Engineering: Corrosion-Resistant Hulls, Decks, and Structures

5086 aluminum plate belongs to Al-Mg series alloy, that is, aluminum-magnesium alloy, and its main alloy element is magnesium. The specific chemical composition (in mass fraction) is as follows:

Magnesium (Mg): 3.5%~4.5%

Silicon (Si): ≤0.40%

Copper (Cu): ≤0.10%

Zinc (Zn): ≤0.25%

Manganese (Mn): 0.20%~0.7%

Titanium (Ti): ≤0.15%

Chromium (Cr): 0.05%~0.25%

Iron (Fe): 0%~0.500% (single impurity ≤ 0.05%, total impurities ≤ 0.15%)

5086 h116 aluminum plate sheet is an aluminum product specially used for ship manufacturing. It inherits all the advantages of 5086 aluminum plate, such as high corrosion resistance, good weld-ability and medium strength, making it widely used in shipbuilding.

In ship manufacturing, 5086 marine grade aluminum navy plates are mainly used for ship plates, decks, engine mounts, ship sides, bottom outer plates and other components.

These components need to withstand the dual test of corrosion and mechanical stress in the marine environment, and the high corrosion resistance and medium strength of 5086 marine grade aluminum navy plate enable them to meet these requirements.

5086 h116 aluminum plate is a rust-proof aluminum plate with medium strength, good corrosion resistance and excellent weld-ability. Its main chemical components include elements such as magnesium, silicon, copper, zinc, manganese and titanium.

What are main application of 5086 aluminum plate?

5086 aluminum plate is widely used in many fields due to its excellent properties:

Ship manufacturing: used to manufacture hulls, decks, ship structural parts, etc., especially suitable for ships that have been in harsh seawater media and marine environments for a long time.

Automotive industry: used in the manufacture of automobile fuel tanks, bodywork and internal structural parts, etc., helping to reduce the weight of automobiles and improve energy efficiency and safety.

Pressure vessels and storage tanks: Used to manufacture pressure vessels and storage tanks that require strict fire protection, such as liquefied natural gas (LNG) storage tanks, tank trucks, etc., to ensure the safety and durability of the containers.

Marine engineering: used in offshore platforms, offshore oil drilling platforms and other equipment, and is favored for its corrosion resistance.

Aerospace: In the aerospace field, the lightweight properties of 5086 aluminum plates make it suitable for the manufacture of aircraft structures and aerospace parts.

Construction field: It can be used to manufacture corrosion-resistant door and window frames, curtain wall systems, and building structural components for outdoor environments and highly corrosive environments.

Military equipment: Due to its corrosion resistance and non-magnetic properties, 5086 aluminum plates are also used to manufacture military equipment, such as certain parts of armored vehicles.

Available aluminum sheet grade

1000 series: 1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series: 2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series: 3003,3004,3102,3104,3105,3005, etc.

4000 series: 4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series: 6061,6063,6262,6101, etc

7000 series: 7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H: H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

5086 aluminum coils is one of the representative products of the marine aluminum sheet. 5086 aluminum sheet prices are generally high, which is inseparable from its complex production process and stable product performance

5086 is an aluminum alloy, primarily alloyed with magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material

Aluminum 5086 is structural alloy, which offers users strong corrosion resistance and high electrical conductivity

5086 aluminum-magnesium alloy and aluminum-manganese alloy are collectively referred to as 5086 anti-rust aluminum plate. Because the alloy composition between the two increases their anti-corrosion function, the representatives of aluminum-manganese alloy are 3003, 3004, 3105, and the aluminum-magnesium alloy is based on the content of magnesium alloy. The order of high and low is 5005, 5252, 5251, 5050, 5052, 5754, 5083, 5056, 5086 and so on.

5086 aluminums have excellent resistance against seawater and can be strengthened through strain hardening or cold working. It also has good weldability. It is not heat treatable.

5086 aluminium is not heat treated, 5086 plate is easy to form, stamp and weld. The main alloying elements of 5086 aluminium alloy are magnesium and silicon

5086 aluminium sheet belongs to 5000 series alloy and is one of the key products of 5000 series aluminium plate. 5086 aluminium plates have higher strength than 5052 and 5083 plates. 5086 aluminium plate is particularly resistant to salt water corrosion. Because 5086 aluminium is not heat treated, 5086 plate is easy to form, stamp and weld.

parameter

|

Thickness |

0.2-6.0mm |

|

Width |

100-2400mm |

|

Length |

200-11000mm |

|

Mother coil |

CC or DC |

|

Weight |

About 2mt per pallet for general size |

|

MOQ |

5ton per size |

|

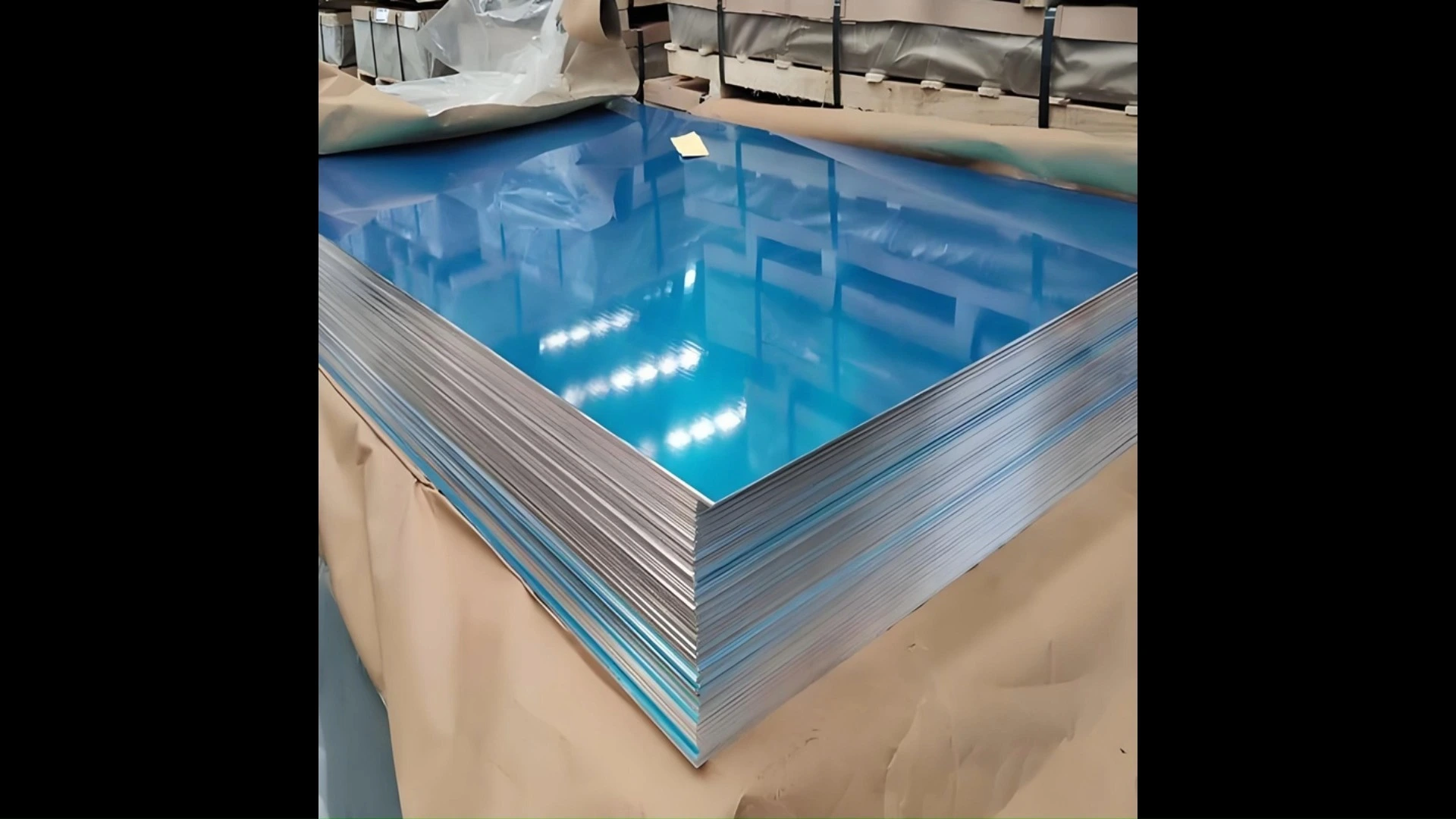

Protection |

paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement. |

|

Surface |

clean and smooth, no bright speck, corrosion, oil, slotted, etc. |

|

Standard product |

GBT3880, JIS4000, EN485, ASTM-B209 |

|

Delivery time |

about 30days after receiving the deposit |

|

Payment |

T/T, L/C at sight |

|

Trading terms |

FOB, CIF, CFR |

Application