3105 Aluminum Plate for Electronic Equipment Installation

3105 aluminum plate is an aluminum alloy material with excellent properties.

The hardness of 3105 aluminum plate is about HB45-55, the tensile strength is 95-140MPa, and it has high strength and hardness.

3105 aluminum plate is stable against oxidation, corrosion and other chemical properties. It can maintain good performance for a long time in many corrosive media and is particularly resistant to atmospheric and seawater corrosion.

3105 aluminum plate has good adaptability to processes such as processing, riveting, deep drawing, welding and cutting, and can be processed into a variety of complex shapes. 3105 aluminum plate has good welding performance and can be welded by conventional TIG, MIG and arc welding methods.

3105 aluminum plate has good thermal conductivity and can be used in applications that require high heat dissipation performance, such as making radiators.

3105 aluminum plate has excellent electrical properties and can be used to make electrical wires and cables for electrical, electrification and rail transit equipment.

The application of 3105 aluminum plate

Construction field: 3105 aluminum panels are often used as decorative materials such as exterior wall panels and roof panels. They are favored for their light weight, high strength, beauty and durability.

Transportation field: 3105 aluminum plates are often used to manufacture parts of transportation vehicles such as automobile bodies and high-speed train carriages, contributing to the lightweighting of transportation vehicles.

Electronics and packaging field: 3105 aluminum plate is widely used in electronic product casings, packaging containers and other fields due to its good conductivity and plasticity.

Other fields: 3105 aluminum plates can also be used to make home appliance casings, radiators, pipes, storage tanks, etc., as well as some low-pressure pipes and storage tanks to meet different application needs.

Available aluminum sheet grade

1000 series: 1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series: 2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series: 3003,3004,3102,3104,3105,3005, etc.

4000 series: 4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series: 6061,6063,6262,6101, etc

7000 series: 7072,7075,7003 etc

8000 series: 8011, etc.

Aluminium / Aluminum 3105 alloy has average machinability. However, its machinability can be increased in harder tempers than in annealed condition. Oil lubricants are used for machining this alloy

Aluminium / Aluminum 3105 alloy has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2 t range for annealed H12, H14 and H16 tempers. Bend radii of 2 to 7 t should be used for the H18 temper

Aluminium / Aluminum 3105 alloy does not react to heat treatment except during cold working.

Aluminium / Aluminum 3105 alloy is used in sheet metal work. It is also used in manufacturing mobile homes, residential siding, and rain carrying goods.

3105 aluminum is a 3000-series aluminum alloy: the main alloying addition is manganese, and it is formulated for primary forming into wrought products. 3105 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-3105.

3105 aluminum sheet is 98% pure aluminum with the addition of specific alloys for strength improvement. This alloy can’t be hardened by heat treatment. It has excellent weldability, formability, and corrosion resistance

parameter

|

Thickness |

0.2-6.0mm |

|

Width |

100-2400mm |

|

Length |

200-11000mm |

|

Mother coil |

CC or DC |

|

Weight |

About 2mt per pallet for general size |

|

MOQ |

5ton per size |

|

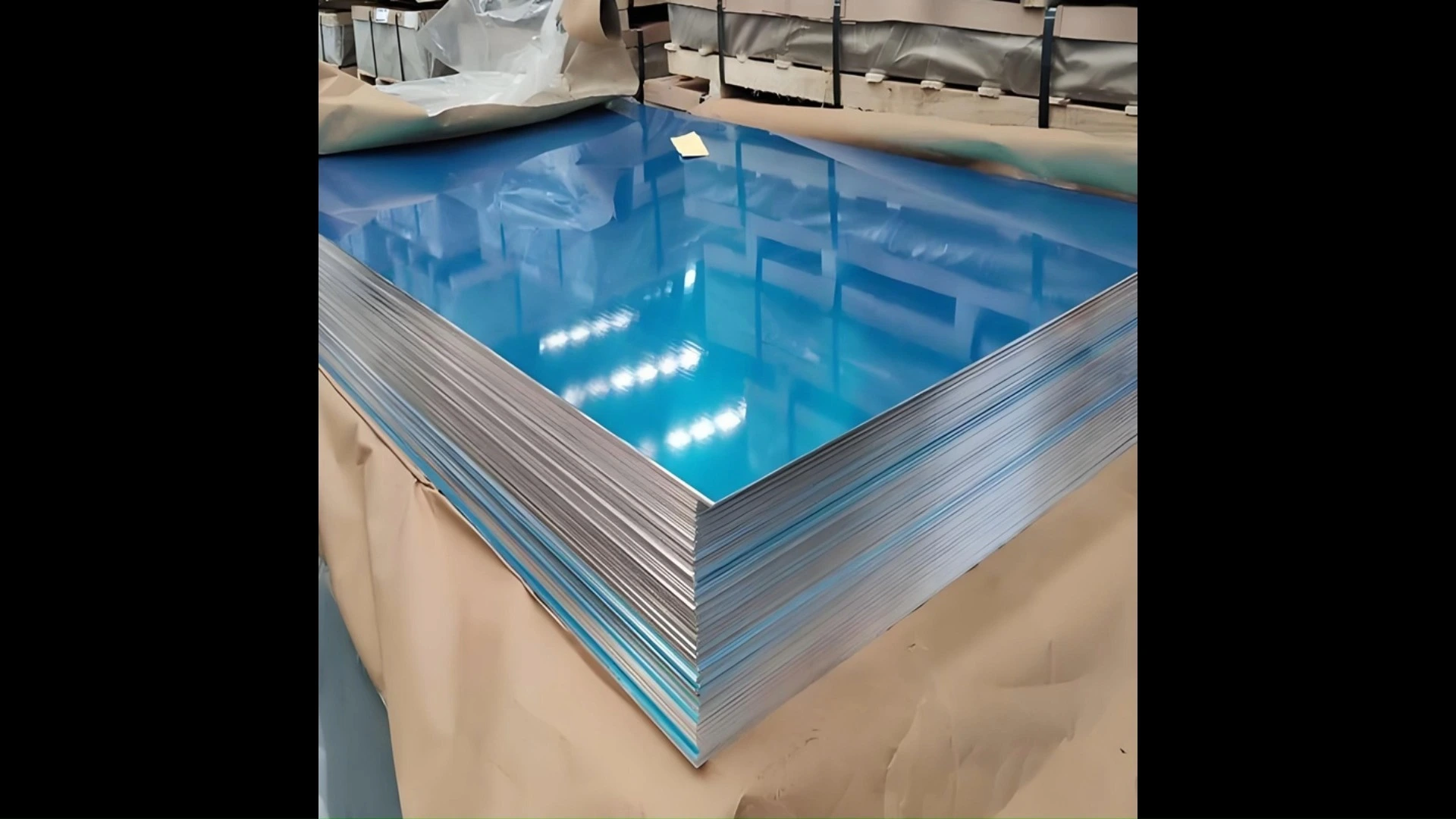

Protection |

paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement. |

|

Surface |

clean and smooth, no bright speck, corrosion, oil, slotted, etc. |

|

Standard product |

GBT3880, JIS4000, EN485, ASTM-B209 |

|

Delivery time |

about 30days after receiving the deposit |

|

Payment |

T/T, L/C at sight |

|

Trading terms |

FOB, CIF, CFR |

Application