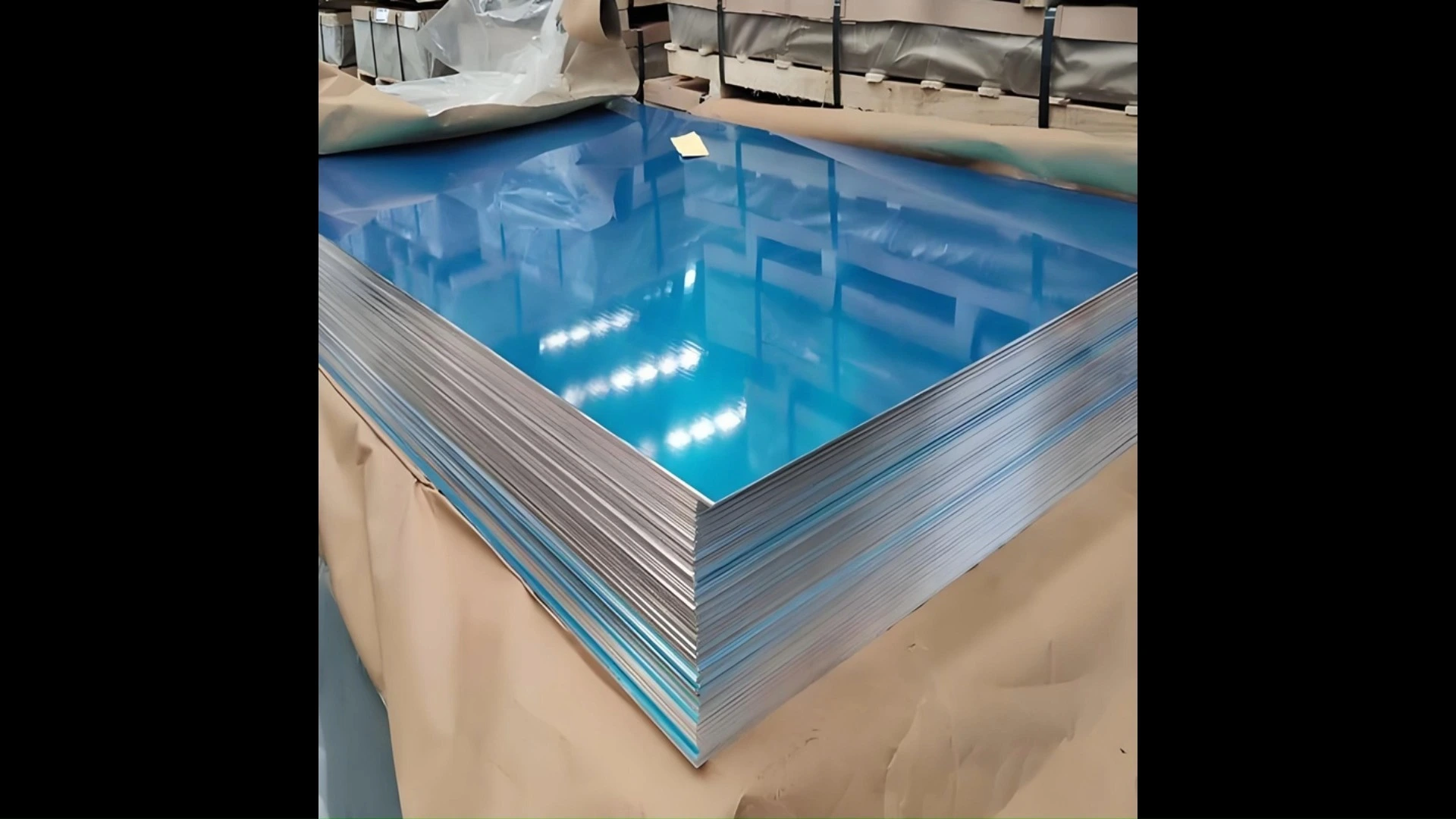

3003 Aluminum Plate

3003 aluminum applications generally require high corrosion resistance and formability, such as kitchenware, sheet metal, and food & chemical equipment

With the Mn element, 3003 aluminum alloy has higher strength. Its strength and hardness is 10% higher than that of 1100 aluminum plate. With excellent rust resistance, 3003 aluminum alloy is widely for pipeline insulation. 1100 aluminum sheet has higher aluminum content.

Heat treatment: 3003 aluminum plate cannot be strengthened by heat treatment, so cold working method is used to improve its mechanical properties. In the annealed state, it has high plasticity; in semi-cold work hardening, the plasticity is still good; in cold work hardening, the plasticity decreases.

Weldability: 3003 aluminum plate has good welding performance and can be used in various welding processes.

Machinability: The machinability of 3003 aluminum plates is poor. Care must be taken to select appropriate cutting tools and parameters during processing.

Aluminum Alloy 3003 is a widely used medium strength aluminum alloy with manganese as its primary alloying element. It has good formability, and may be suitable for applications that require bending, spinning, drawing, stamping and roll forming.

3003 aluminum plate is widely used in many fields due to its excellent anti-rust properties and good processing performance:

Kitchenware manufacturing: used to make various cooking utensils and tableware, such as pots, plates, bowls, etc.

Food and chemical processing: used to make processing and storage devices such as tanks, tanks, etc.

Transportation field: used to make liquid storage tanks, tanks and pressure vessels to meet the needs of transporting liquid products. In addition, it is also commonly used to make fuel tanks, gasoline or lubricating oil conduits, etc.

Other fields: It is also widely used in cosmetic boards, photocopier rollers, ship materials, outer packaging, mechanical parts, refrigerators, air conditioning and ventilation ducts, etc. In particular, 3003 aluminum plates are favored for their good anti-rust capabilities in humid environments

Available aluminum sheet grade

1000 series: 1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series: 2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series: 3003,3004,3102,3104,3105,3005, etc.

4000 series: 4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series: 6061,6063,6262,6101, etc

7000 series: 7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H: H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

Aluminum Alloy 3003 is a widely used medium strength aluminum alloy with manganese as its primary alloying element. It has good formability, and may be suitable for applications that require bending, spinning, drawing, stamping and roll forming.

3003 aluminum is alloyed with 1.2% manganese to provide a tensile strength range of 17000 to 30000 psi. It has excellent forming characteristics and corrosion resistance and is weldable.

parameter

|

Thickness |

0.2-6.0mm |

|

Width |

100-2400mm |

|

Length |

200-11000mm |

|

Mother coil |

CC or DC |

|

Weight |

About 2mt per pallet for general size |

|

MOQ |

5ton per size |

|

Protection |

paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement. |

|

Surface |

clean and smooth, no bright speck, corrosion, oil, slotted, etc. |

|

Standard product |

GBT3880, JIS4000, EN485, ASTM-B209 |

|

Delivery time |

about 30days after receiving the deposit |

|

Payment |

T/T, L/C at sight |

|

Trading terms |

FOB, CIF, CFR |

Application