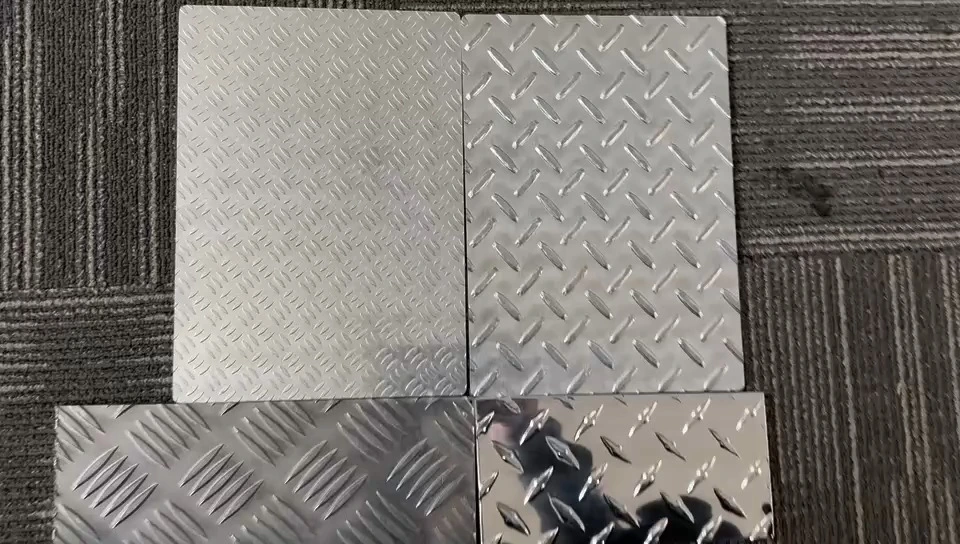

3003 Aluminum checkered Plate Sheet

3003 Aluminum alloy is the most widely used of all aluminum alloys. It is essentially commercially pure aluminum with the addition of Manganese which increases strength some 20% over 1100. With excellent corrosion resistance and workability it can be deep drawn or spun, welded or brazed.

3003, 4017 and 5052 aluminum tread plate is available in full size and custom cut lengths in our factory.

The 3003 h22 aluminum tread plate is made of rust-proof 3000 series AL-MN aluminum alloy and other billets through equipment rolling.

3003 H22 aluminum has better properties, with highly cost-effective and practical. As for the h22 of 3003 h22 aluminum, refers to the H22 tempering state and the 2 hardening degree obtained, after processing hardening and incomplete annealing of 3003 aluminum. Meanwhile, the strength of 3003 h22 is between annealed (O) and full-hard (H28).

3003 h22 aluminum properties also show excellent formability, ductility, processability, surface handling, weldability, corrosion resistance, etc. So aluminium 3003 h22 sheet alloy is widely used for architectural decoration, marine, vehicle transportation, manufacturing, and other fields.

3003 alloy aluminum have equivalent name like A3003, 3003a, aa3003, 3003aa, al3003, al3003a, a 3003, aa 3003, jis a3003p, al3003 class, aw3003, en3003 grade etc.

3003 h22 aluminum diamond plate always shows features like lightweight, highly polished surface, concise, durability, as well as better formability, weldability, skid & corrosion resistance, no low-temperature brittleness, etc.

3003 aluminum checker plate

3003 aluminum chequered plate is a type of aluminum alloy plate that is commonly used for its excellent corrosion resistance, high strength, and good workability. It is often used in various applications such as flooring, stairs, ramps, and decorative purposes.

The chequered pattern on the plate provides added grip and traction, making it suitable for areas where slip resistance is important. It is also commonly used in transportation, construction, and marine industries.

3003 aluminum chequered plate typically has a thickness ranging from 1.0mm to 8.0mm, and the width and length can be customized according to specific requirements. It is available in various finishes such as mill finish, brushed, and embossed.

Some advantages of 3003 aluminum chequered plate include its lightweight nature, durability, and low maintenance requirements. It is also easy to clean and has good weather resistance.

Overall, 3003 aluminum chequered plate is a versatile and cost-effective option for various applications that require a combination of strength, corrosion resistance, and slip resistance.

parameter

|

Checkered patterns |

one bar, two bar, 3 bars, 5 bar, diamond, embossed, decorative |

|

Surface treatment |

Mill finish, PE coated, mirror finished |

|

Alloy Type |

1050/1060/1070/1100/1200/1350/3003/3004/3105/5005/5052/5754/5083 |

|

Thickness |

0.2–20.0mm or custom |

|

Width |

30-2600mm or custom |

|

Length |

100-10000mm |

|

Temper |

O/H12/H22/H14/H24/H16/H26/H18/H32 |

|

Weight |

1-5ton per pallet |

|

MOQ |

5-10ton per size |

|

Protection |

Paper inter layer or blue film |

|

Standard product |

GBT3880, JIS4000, EN485, ASTM-B209 |

|

Delivery time |

about 30days after receiving the deposit |

|

Payment |

T/T, L/C at sight |

|

Trading terms |

FOB, CIF, CFR |

Application

Aluminum checker plate is widely used in decorative, shipbuilding and architectural applications. Having good forming, drilling and welding ability, Aluminum Diamond Plate is easy to fabricate and its raised

Applications: Aluminum checker plate such as van-type vehicle catwalk flooring, wood step of the bus or truck, train inspection hole lid, tank car, the car cold storage.

Ship

Applications: corridor and bridges over the lid and floors, stairs, cabin deck, fish tank, gangway to the floating dock.

Applications: floors, stairs, shelves, such as gutter lid, the bicycle.

Applications: bench floor and stairs, equipment/ plant machinery, such as ambulatory inspection.

Applications: such as a deck ladder, ladder, showcase, temporary scaffolding, the structure of marine.

Product Display