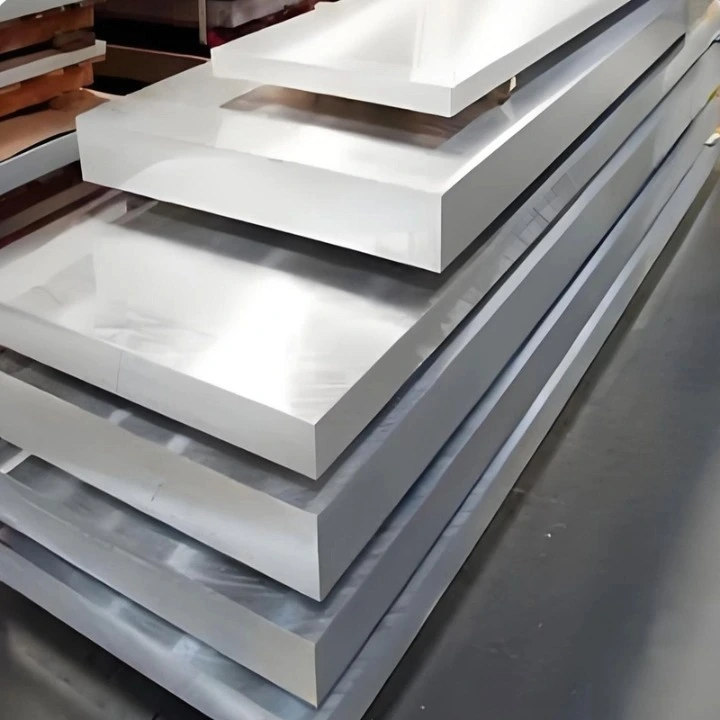

7055 Aircraft Aluminum Plate for Aircraft Wing, Fuselage, Engine Housing, Landing Gear and Engine Room Interior Parts

7055 Aircraft Aluminum Plate, also called aviation aluminum sheet or aerospace aluminum plate, has wide application prospects in aerospace, high-speed trains, shipbuilding and other fields due to its high strength, good corrosion resistance and welding performance.

SAE AMS 4206 specifies the standard specification for 7055-T7751 aluminum alloy sheet, including the chemical composition, mechanical properties, machinability, corrosion properties and other requirements of the material.

Specification of 7055 T7751 aluminum plate

| Thickness(mm) | 0.5-600 |

| Width(mm) | <2650 |

| Length(mm) | <8000 |

| Standard | GB/T3880, GJB1541, GJB2662, STMB209, EN485, ASTM B209, AMS 4206, QQ-A-250, MIL-HDBK-5 |

Chemical composition of 7055 aluminum aerospace plate

| Element | Composition(%) |

| Al | Remainder |

| Si | ≤0.10 |

| Fe | ≤0.15 |

| Cu | 2.0-2.6 |

| Mn | ≤0.50 |

| Mg | 1.8-2.3 |

| Cr | ≤0.04 |

| Ni | / |

| Zn | 7.6-8.4 |

| Ti | ≤0.06 |

| Zr | 0.05-0.25 |

| Other | Single:≤0.05 Total:≤0.15 |

Available aluminum sheet grade

1000 series: 1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series: 2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series: 3003,3004,3102,3104,3105,3005, etc.

4000 series: 4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series: 6061,6063,6262,6101, etc

7000 series: 7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H: H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

7055 aviation aluminum alloy plate is a kind of high strength aluminum alloy material, its mechanical performance is excellent, the common mechanical property parameters include the following aspects:

Tensile strength: at room temperature, the tensile strength of 7055 aluminum plate is generally between 600 MPa and 680 MPa.

Yield strength: at room temperature, the yield strength of 7055 aluminum plate is generally between 480 MPa and 510 MPa.

Elongation: at room temperature, the elongation of 7055 aluminum plate is generally between 6% and 7%.

Impact toughness: 7055 aluminum plate impact toughness is better, can reach 45 J/cm2 above.

7055 aviation aluminum plates are widely used in the aerospace field, such as used in the manufacture of aircraft fuselages, landing gears, engine parts and other key parts. Its high strength and high corrosion resistance can ensure the safety and reliability of aircraft.

7055 aluminum plates are also suitable for the manufacture of brake discs, body structures and other components of high-speed trains, and can meet the material strength and durability requirements of high-speed trains.

In the field of shipbuilding, 7055 aluminum alloy can be used to manufacture hull structures, ship equipment and other parts to improve the safety and reliability of ships.

7055 aluminum alloy can also be used to manufacture structural parts of high-rise buildings, curtain walls, doors and windows and other building components, as well as components in the power and electronic fields such as cable brackets and transformer shells.

parameter

|

Thickness |

0.2-6.0mm |

|

Width |

100-2400mm |

|

Length |

200-11000mm |

|

Mother coil |

CC or DC |

|

Weight |

About 2mt per pallet for general size |

|

MOQ |

5ton per size |

|

Protection |

paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement. |

|

Surface |

clean and smooth, no bright speck, corrosion, oil, slotted, etc. |

|

Standard product |

GBT3880, JIS4000, EN485, ASTM-B209 |

|

Delivery time |

about 30days after receiving the deposit |

|

Payment |

T/T, L/C at sight |

|

Trading terms |

FOB, CIF, CFR |

Application