The Benefits Of Using Anodized Aluminum Plate In Your Construction Projects

Are you looking for a durable and versatile material to use in your construction projects? Look no further than anodized aluminum plate. In this article, we will discuss the numerous benefits of using anodized aluminum in construction, from its superior strength and corrosion resistance to its sleek and modern aesthetic. Stay tuned to discover how anodized aluminum can elevate your building projects to new heights.

- An Overview of Anodized Aluminum Plate

An Overview of Anodized Aluminum Plate

Anodized aluminum plate is a popular material used in construction projects for its numerous benefits and advantages. In this article, we will delve into the various reasons why anodized aluminum plate is a preferred choice for builders and contractors alike.

One of the key advantages of using anodized aluminum plate is its durability. The anodizing process involves coating the aluminum surface with a protective layer, which makes the material highly resistant to corrosion and wear. This protective layer also helps to prevent scratches, abrasions, and other forms of damage, ensuring that the aluminum plate maintains its pristine appearance for years to come.

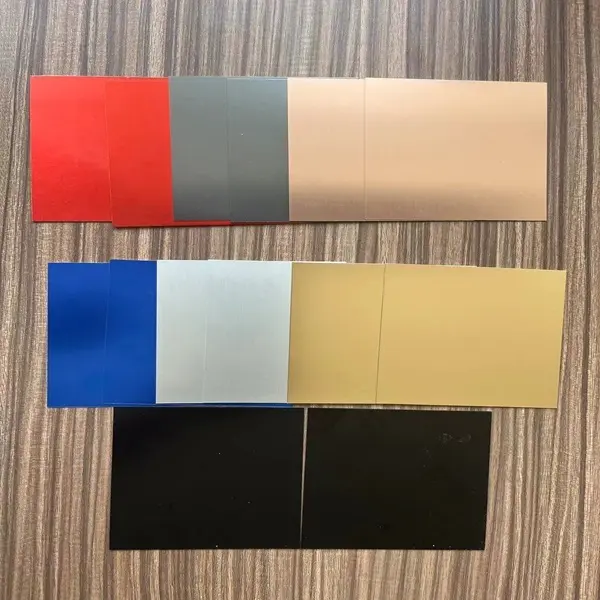

In addition to its durability, anodized aluminum plate is also known for its attractive finish. The anodizing process allows for a wide range of colors and finishes to be applied to the aluminum surface, giving builders and designers the flexibility to customize the material to suit their aesthetic preferences. Whether you prefer a sleek, modern look or a more traditional appearance, anodized aluminum plate can be tailored to meet your specific design needs.

Furthermore, anodized aluminum plate is lightweight and easy to work with, making it an ideal choice for a wide range of construction applications. Its lightweight nature makes it easy to transport and install, while its malleability allows for easy bending and shaping to fit the contours of any building or structure. This versatility makes anodized aluminum plate an excellent choice for projects of all sizes and scopes.

Another key benefit of using anodized aluminum plate is its sustainability. Aluminum is a highly recyclable material, which means that anodized aluminum plate can be easily recycled and reused at the end of its life cycle. This makes it a more environmentally friendly option compared to other building materials, contributing to a more sustainable and eco-conscious construction industry.

In conclusion, anodized aluminum plate offers a wide range of benefits for construction projects, including durability, aesthetics, versatility, and sustainability. Its ability to withstand wear and tear, its customizable finishes, its ease of workability, and its recyclability make it a top choice for builders and designers looking for a reliable and sustainable construction material. Next time you embark on a construction project, consider using anodized aluminum plate for a high-quality and long-lasting result.

- Increased Durability and Corrosion Resistance

Anodized aluminum plate is a popular material used in construction projects for its enhanced durability and corrosion resistance. When aluminum undergoes the anodizing process, a protective oxide layer is formed on its surface, making it more resistant to wear and tear from daily use. This added layer not only increases the material's lifespan but also protects it from rust and corrosion, making it a cost-effective choice for long-term construction projects.

One of the key benefits of using anodized aluminum plate in construction projects is its increased durability. The anodizing process creates a hard, durable surface that is resistant to scratches and dents. This means that anodized aluminum plate is less likely to show signs of wear and tear over time, making it a low-maintenance option for builders and contractors. The material's durability also makes it ideal for high-traffic areas, where it will be subjected to constant use and potential damage.

In addition to its durability, anodized aluminum plate also offers superior corrosion resistance. The protective oxide layer formed during the anodizing process helps prevent the material from rusting, even when exposed to harsh environmental conditions such as moisture, salt, and chemicals. This makes anodized aluminum plate an excellent choice for outdoor construction projects, where traditional metal materials may be prone to corrosion over time. By using anodized aluminum plate, builders can ensure that their structures will remain strong and stable for years to come.

Another advantage of anodized aluminum plate is its aesthetic appeal. The anodizing process allows for a wide range of colors and finishes to be applied to the material, giving builders the opportunity to customize their projects to suit their design preferences. Whether a sleek, modern look is desired or a more traditional appearance is preferred, anodized aluminum plate can be tailored to meet the specific aesthetic requirements of any construction project. This versatility, combined with its durability and corrosion resistance, makes anodized aluminum plate a popular choice among architects, designers, and builders.

In conclusion, the benefits of using anodized aluminum plate in construction projects are clear. Its increased durability and corrosion resistance make it a reliable and cost-effective material for a wide range of applications. Whether used in high-traffic areas, outdoor structures, or customized design projects, anodized aluminum plate offers builders and contractors a versatile and long-lasting solution. By choosing anodized aluminum plate for their construction projects, builders can ensure that their structures will stand the test of time while maintaining a visually appealing appearance.

- Enhanced Aesthetics and Design Flexibility

When it comes to construction projects, every detail matters. From the materials used to the finishing touches, every aspect of a building can impact its overall appearance and functionality. One material that is gaining popularity in the construction industry is anodized aluminum plate. This versatile material offers a range of benefits, including enhanced aesthetics and design flexibility.

Anodized aluminum plate is a type of aluminum that has been treated with an electrochemical process to create a durable, corrosion-resistant finish. This finish not only helps protect the aluminum from the elements, but it also gives it a sleek, modern look that is perfect for contemporary construction projects. The anodizing process can also be customized to create a wide range of colors and finishes, allowing architects and designers to create unique and eye-catching designs.

One of the key benefits of using anodized aluminum plate in construction projects is its enhanced aesthetics. The smooth, shiny finish of anodized aluminum can instantly elevate the look of a building, adding a touch of sophistication and modernity. Whether used for exterior cladding, interior finishes, or decorative elements, anodized aluminum plate can help create a cohesive and polished look that will impress clients and visitors alike.

In addition to its aesthetic benefits, anodized aluminum plate also offers design flexibility. Unlike other materials, such as steel or concrete, aluminum is lightweight and easy to work with, making it ideal for complex and innovative architectural designs. Anodized aluminum plate can be easily cut, shaped, and molded to create a wide range of custom shapes and sizes, allowing designers to bring their visions to life with ease.

Furthermore, anodized aluminum plate is a sustainable choice for construction projects. Aluminum is a highly recyclable material, which means that it can be reused and repurposed for future projects. By choosing anodized aluminum plate for construction projects, architects and designers can reduce their environmental impact and contribute to a more sustainable building industry.

In conclusion, the benefits of using anodized aluminum plate in construction projects are clear. From enhanced aesthetics to design flexibility, this versatile material offers a range of advantages that make it an excellent choice for modern buildings. Whether used for exterior cladding, interior finishes, or decorative elements, anodized aluminum plate can help create a stylish and sustainable building that will stand the test of time.

- Cost-Efficiency and Sustainability

Anodized aluminum plate is a popular construction material known for its cost-efficiency and sustainability. When compared to other materials, anodized aluminum plate offers numerous benefits that make it an attractive choice for construction projects of all sizes.

Cost-efficiency is a critical factor to consider when embarking on a construction project. Anodized aluminum plate is not only affordable but also offers long-term cost savings. Due to its durability and resistance to corrosion, anodized aluminum plate requires minimal maintenance, reducing the need for costly repairs or replacements over time. Additionally, the lightweight nature of aluminum makes it easy to transport and install, saving on labor costs and time.

Sustainability is another key advantage of using anodized aluminum plate in construction projects. Aluminum is 100% recyclable, making it a green building material choice. By choosing anodized aluminum plate, builders can reduce their carbon footprint and contribute to a more sustainable environment. Furthermore, the anodizing process used to treat aluminum plate generates minimal waste and is less harmful to the environment than other coating methods.

In addition to cost-efficiency and sustainability, anodized aluminum plate offers a range of practical benefits that make it an ideal material for construction projects. The anodizing process creates a protective oxide layer on the surface of the aluminum, making it highly resistant to scratches, UV rays, and harsh weather conditions. This ensures that the aluminum plate will maintain its appearance and structural integrity for years to come.

Furthermore, anodized aluminum plate is available in a variety of colors and finishes, allowing builders to achieve a customized look for their projects. Whether used for roofing, cladding, or decorative elements, anodized aluminum plate can enhance the aesthetic appeal of any building while providing superior performance and durability.

In conclusion, the benefits of using anodized aluminum plate in construction projects are evident. Its cost-efficiency, sustainability, durability, and aesthetic versatility make it a top choice for builders looking to optimize their projects for long-term success. By investing in anodized aluminum plate, builders can achieve both practical and aesthetic goals while contributing to a more sustainable future for the construction industry.

- Conclusion: Advantages of Anodized Aluminum Plate in Construction

Anodized aluminum plate is a versatile and durable material that is becoming increasingly popular in the construction industry. With a wide range of benefits and advantages, anodized aluminum plate is a smart choice for any construction project.

One of the main advantages of anodized aluminum plate is its durability. The anodizing process creates a hard, protective layer on the surface of the aluminum, making it resistant to corrosion, scratches, and wear and tear. This makes anodized aluminum plate an ideal choice for exterior applications where the material is exposed to the elements.

In addition to its durability, anodized aluminum plate is also lightweight and easy to work with. This makes it a practical choice for a wide range of construction projects, including roofing, facades, windows, and doors. The lightweight nature of anodized aluminum plate also reduces the overall weight of the building, which can help to reduce construction costs.

Another key advantage of anodized aluminum plate is its aesthetic appeal. The anodizing process can be used to create a wide range of colors and finishes, making it easy to match the material to the design of the building. This allows for greater design flexibility and the ability to create a unique and visually appealing finished product.

Anodized aluminum plate also offers environmental benefits. The anodizing process is non-toxic and produces minimal waste, making it a more sustainable option compared to other materials. Additionally, anodized aluminum plate is 100% recyclable, making it a more environmentally friendly choice for construction projects.

Overall, the advantages of using anodized aluminum plate in construction are clear. Its durability, lightweight nature, aesthetic appeal, and environmental benefits make it a smart choice for a wide range of construction projects. Whether you are building a modern high-rise or a sleek commercial storefront, anodized aluminum plate is a material that should be considered for its many benefits.

Conclusion

In conclusion, the benefits of using anodized aluminum plate in construction projects are undeniable. This versatile material offers durability, corrosion resistance, and aesthetic appeal, making it a popular choice for a wide range of applications in the construction industry. Whether you are working on a small residential project or a large commercial development, incorporating anodized aluminum plate into your design can help ensure a successful and long-lasting result. So, next time you are planning a construction project, consider the many advantages that anodized aluminum plate has to offer. Your project will not only look great but also stand the test of time.