Exploring The Versatility Of Aluminium Plate: From Fabrication To Applications

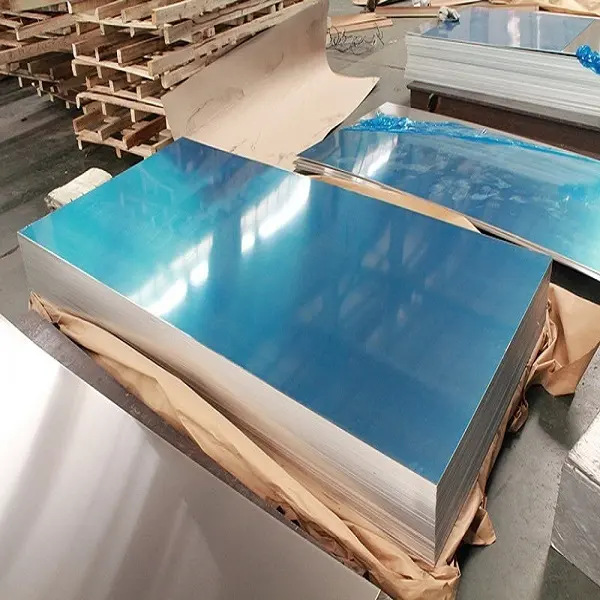

Aluminium plate is a material that is known for its versatility and durability, making it a popular choice for a wide range of applications. From fabrication to various uses, this article delves into the many ways in which aluminium plate can be utilized. Whether you are in the manufacturing industry or simply interested in learning more about this versatile material, this article will provide you with valuable insights into the world of aluminium plate and the endless possibilities it offers. Join us as we explore the endless potential of aluminium plate and its diverse applications.

- Understanding the Properties of Aluminium Plate

Aluminium plate is a versatile material that finds its way into a wide range of industries due to its unique properties. From its fabrication to its various applications, understanding the properties of aluminium plate is crucial to ensure its successful use in different settings.

One of the key characteristics of aluminium plate is its lightweight nature. Despite its low density, aluminium plate is remarkably strong, making it an ideal material for applications where weight is a concern, such as in the aerospace and automotive industries. Its high strength-to-weight ratio allows for the creation of sturdy structures without adding unnecessary bulk.

In addition to being lightweight and strong, aluminium plate is also highly corrosion resistant. This makes it an excellent choice for outdoor applications where exposure to the elements is a concern. Whether it's being used in construction projects or in marine environments, aluminium plate can withstand the test of time without deteriorating due to rust or corrosion.

Another important property of aluminium plate is its excellent thermal conductivity. This makes it a popular choice for heat transfer applications, such as in the manufacturing of heat exchangers or cooling systems. Additionally, aluminium plate is a good conductor of electricity, making it suitable for use in electrical applications where conductivity is important.

When it comes to fabrication, aluminium plate is easily machinable and weldable, making it a versatile material for creating complex shapes and structures. Its malleability allows for easy forming and shaping, while its weldability ensures strong and secure joints. This makes aluminium plate a popular choice for manufacturers looking to create custom components for a wide range of industries.

The applications of aluminium plate are virtually endless. From automotive body panels to aircraft wings, from heat sinks to cookware, aluminium plate can be found in a variety of products and industries. Its versatility and durability make it a valuable material for both commercial and industrial use.

In conclusion, understanding the properties of aluminium plate is essential for utilizing its full potential in various applications. Its lightweight nature, excellent corrosion resistance, thermal conductivity, and ease of fabrication make it a standout material in the world of manufacturing. With its wide range of applications and benefits, aluminium plate continues to be a popular choice for engineers and designers alike.

- Techniques for Fabricating Aluminium Plate

Aluminium plate is a versatile material that is widely used in various industries due to its durability, lightweight properties, and corrosion resistance. In this article, we will explore the techniques for fabricating aluminium plate, from shaping and cutting to welding and finishing.

One of the most common techniques for fabricating aluminium plate is shaping. Aluminium plate can be easily shaped using various methods, such as bending, rolling, and stamping. Bending is often used to create curved or angled shapes, while rolling is used to flatten the plate or create cylindrical shapes. Stampings are used to create intricate designs or patterns on the surface of the plate.

Cutting is another crucial technique for fabricating aluminium plate. There are several methods for cutting aluminium plate, including shearing, sawing, and laser cutting. Shearing is a process that involves cutting the plate using a sharp blade, while sawing uses a saw blade to cut through the plate. Laser cutting, on the other hand, uses a high-powered laser to cut through the plate with precision and accuracy.

Once the aluminium plate has been shaped and cut, it can be joined together using welding techniques. One of the most common welding techniques for aluminium plate is gas metal arc welding (GMAW), also known as MIG welding. GMAW uses a consumable electrode wire to join the plates together, creating a strong bond. Another welding technique that is commonly used for aluminium plate is tungsten inert gas (TIG) welding, which uses a non-consumable tungsten electrode to create a weld pool that joins the plates together.

After the aluminium plate has been shaped, cut, and welded, it can be finished to enhance its appearance and durability. One common finishing technique for aluminium plate is anodizing, which involves coating the plate with a protective oxide layer to prevent corrosion and improve its resistance to wear and tear. Another finishing technique is powder coating, which involves applying a dry powder to the surface of the plate and then curing it with heat to create a durable and attractive finish.

In conclusion, aluminium plate is a versatile material that can be fabricated using a variety of techniques, from shaping and cutting to welding and finishing. By understanding these techniques and how they can be applied, manufacturers and fabricators can take full advantage of the versatility of aluminium plate and create high-quality products for a wide range of applications.

- Diverse Applications of Aluminium Plate in Various Industries

Aluminium plate is a versatile material that is widely used in various industries for its durability, lightweight properties, and corrosion resistance. From fabrication to applications, aluminium plate plays a crucial role in the manufacturing process of a variety of products. In this article, we will explore the diverse applications of aluminium plate in different industries.

One of the key industries that rely heavily on aluminium plate is the automotive industry. Aluminium plate is used in the fabrication of car parts such as body panels, chassis components, and heat shields. Its lightweight nature helps to reduce the overall weight of the vehicle, improving fuel efficiency and performance. Additionally, aluminium plate is highly malleable, making it easy to form into complex shapes required for automotive applications.

Another industry that benefits from the use of aluminium plate is the aerospace industry. The lightweight properties of aluminium plate make it an ideal material for aircraft construction. From structural components to interior fittings, aluminium plate is used extensively in the fabrication of airplanes and spacecraft. Its high strength-to-weight ratio and resistance to corrosion make it a preferred choice for aerospace applications.

In the construction industry, aluminium plate is used in the fabrication of building facades, roofing systems, and structural components. Its durability and resistance to rust make it a popular choice for outdoor applications. Aluminium plate is also used in the manufacturing of window frames, doors, and other architectural elements due to its aesthetic appeal and ease of maintenance.

The marine industry also relies on aluminium plate for its seawater resistance and low maintenance requirements. Aluminium plate is used in the construction of boats, ship hulls, and marine equipment. Its lightweight properties make it an ideal material for marine applications, helping to improve fuel efficiency and performance on the water.

In the manufacturing industry, aluminium plate is used in a wide range of applications, from machinery components to consumer electronics. Its excellent thermal conductivity makes it a preferred choice for heat sinks and electrical enclosures. The malleability of aluminium plate allows for easy fabrication and customization to meet the specific requirements of different products.

Overall, aluminium plate is a versatile material that finds applications in a wide range of industries due to its durability, lightweight properties, and corrosion resistance. From automotive to aerospace, construction to marine, aluminium plate plays a crucial role in the fabrication and production of a variety of products. Its versatility and adaptability make it a valuable material for modern industrial applications.

- Innovations in Using Aluminium Plate for Structural Purposes

Aluminium plate has long been a popular material in various industries for its lightweight, durable, and corrosion-resistant properties. In recent years, there have been significant innovations in the use of aluminium plate for structural purposes, revolutionizing the way it is fabricated and applied in different applications.

One of the key advancements in the use of aluminium plate for structural purposes is the development of new fabrication techniques that allow for greater precision and efficiency. For instance, laser cutting technology has made it possible to cut aluminium plate with unparalleled accuracy, resulting in components that fit together seamlessly and require minimal finishing. This has opened up new possibilities for designers and engineers looking to push the boundaries of what is possible with aluminium plate.

In addition to improved fabrication techniques, there have also been advancements in the way aluminium plate is formed and shaped. Press braking, for example, is a process that allows for the bending of aluminium plate to create complex shapes and structures. This technique has been widely adopted in the aerospace and automotive industries, where lightweight yet strong components are crucial.

Furthermore, the development of new alloys and treatments has expanded the range of applications for aluminium plate in structural engineering. High-strength aluminium alloys offer a significant strength-to-weight ratio, making them ideal for applications where weight savings are critical. Meanwhile, treatments such as anodizing and powder coating enhance the durability and corrosion resistance of aluminium plate, making it suitable for outdoor and harsh environments.

The versatility of aluminium plate extends beyond manufacturing and fabrication to its applications in various industries. In the construction sector, aluminium plate is increasingly being used in the creation of high-rise buildings, bridges, and other structures due to its excellent strength-to-weight ratio and resistance to corrosion. In the transportation industry, aluminium plate is becoming a popular choice for the construction of lightweight vehicles, reducing fuel consumption and emissions.

Overall, the innovations in using aluminium plate for structural purposes have opened up new opportunities and possibilities for designers, engineers, and manufacturers. With advancements in fabrication techniques, forming processes, alloys, and treatments, aluminium plate is now a versatile and reliable material for a wide range of applications. As the demand for lightweight, strong, and durable materials continues to grow, aluminium plate is poised to play a key role in shaping the future of structural engineering.

- Environmental Benefits of Using Aluminium Plate in Manufacturing Processes

Aluminium plate is a versatile material that has a wide range of applications in various industries, including manufacturing processes. In this article, we will explore the environmental benefits of using aluminium plate in manufacturing processes.

One of the key advantages of using aluminium plate in manufacturing processes is its recyclability. Aluminium is a highly recyclable material, and it can be recycled multiple times without losing its properties. This means that using aluminium plate in manufacturing processes can help reduce the demand for new raw materials and lessen the environmental impact of production.

In addition to being recyclable, aluminium plate is also lightweight and durable. This makes it an ideal material for manufacturing processes as it can help reduce transportation costs and energy consumption. By using aluminium plate in manufacturing processes, companies can also decrease their carbon footprint and contribute to a more sustainable and eco-friendly production process.

Furthermore, aluminium plate is corrosion-resistant, which means that it can withstand harsh environments and weather conditions. This makes it a long-lasting material that can be used in a wide range of applications, from automotive to construction. By using aluminium plate in manufacturing processes, companies can ensure the longevity of their products and reduce the need for frequent maintenance and replacements.

Overall, the environmental benefits of using aluminium plate in manufacturing processes are significant. From its recyclability to its lightweight and durable properties, aluminium plate is a sustainable option that can help companies reduce their carbon footprint and contribute to a more eco-friendly production process. By incorporating aluminium plate into their manufacturing processes, companies can not only improve the quality of their products but also make a positive impact on the environment.

Conclusion

In conclusion, the versatility of aluminium plate is truly remarkable, as demonstrated in its wide range of fabrication processes and countless applications across various industries. From its malleability and strength to its corrosion resistance and lightweight properties, aluminium plate has proven to be an essential material in modern manufacturing and construction. As technology continues to advance, we can only look forward to even more innovative uses for this remarkable material. Whether in aerospace, automotive, construction, or any other industry, aluminium plate will undoubtedly continue to play a crucial role in shaping our future. So, the next time you see a structure or product made from aluminium plate, take a moment to appreciate the craftsmanship and versatility that went into its creation.