Exploring The Many Uses Of Aluminum Sheet Plate: A Versatile And Durable Material

Are you curious about how aluminum sheet plate can enhance various applications in your daily life? Look no further! In this article, we will delve into the diverse uses of this versatile and durable material. From construction to automotive industries, aluminum sheet plate proves to be a valuable asset in numerous sectors. Join us as we explore the many possibilities of this essential material.

- The Properties and Characteristics of Aluminum Sheet Plate

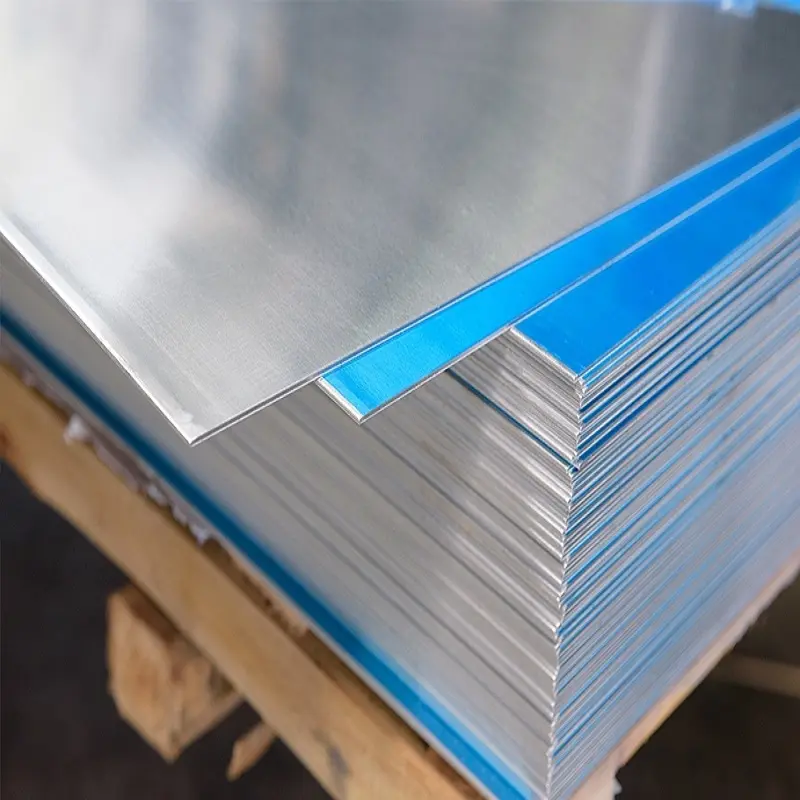

Aluminum sheet plate is a versatile and durable material that has a wide range of uses across various industries. Understanding the properties and characteristics of aluminum sheet plate is crucial in maximizing its potential in different applications.

Firstly, aluminum sheet plate is known for its lightweight nature, making it ideal for applications where weight is a concern. Despite its light weight, aluminum sheet plate is incredibly strong and durable, making it a popular choice for aerospace, automotive, and construction industries. Its high strength-to-weight ratio allows for the creation of structures that are both sturdy and easy to transport.

Another important property of aluminum sheet plate is its corrosion resistance. Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent rust and corrosion. This makes aluminum sheet plate a suitable material for outdoor applications, such as building facades, signage, and marine equipment. Additionally, aluminum sheet plate can be coated with protective finishes to further enhance its resistance to harsh environmental conditions.

Aluminum sheet plate is also highly malleable and can be easily formed into different shapes and sizes. This flexibility allows for the production of complex designs and structures, making aluminum sheet plate a popular choice for architectural and decorative applications. Furthermore, aluminum sheet plate can be easily cut, drilled, and welded, making it a versatile material for custom fabrication projects.

In terms of sustainability, aluminum sheet plate is 100% recyclable and can be recycled repeatedly without losing its original properties. This makes aluminum sheet plate an environmentally-friendly choice for businesses looking to reduce their carbon footprint and minimize waste. Using recycled aluminum sheet plate also helps conserve natural resources and reduce energy consumption during the production process.

Overall, aluminum sheet plate is a highly versatile material with a wide range of properties and characteristics that make it suitable for various applications. Its lightweight nature, corrosion resistance, malleability, and recyclability make aluminum sheet plate a practical and sustainable choice for industries looking for durable and cost-effective solutions. By understanding the properties and characteristics of aluminum sheet plate, businesses can harness the full potential of this versatile material in their projects.

- Common Applications of Aluminum Sheet Plate in Various Industries

Aluminum sheet plate is a versatile and durable material that is used in a wide variety of industries for an array of applications. Its lightweight yet strong properties make it an ideal choice for many different uses, from construction to automotive to aerospace. In this article, we will explore some of the common applications of aluminum sheet plate in various industries.

One of the most common uses of aluminum sheet plate is in the construction industry. Its strength and durability make it an excellent choice for building facades, roofing, and siding. Aluminum sheet plate is also used in the manufacturing of doors, windows, and other architectural elements. Its corrosion resistance makes it a popular material for outdoor structures that need to withstand the elements.

In the automotive industry, aluminum sheet plate is used in the manufacturing of car bodies, chassis, and other structural components. Its lightweight properties help to improve fuel efficiency and reduce emissions. Aluminum sheet plate is also used in the production of heat shields, exhaust systems, and other automotive parts that require high strength and heat resistance.

In the aerospace industry, aluminum sheet plate is prized for its strength-to-weight ratio and corrosion resistance. It is used in the construction of aircraft bodies, wings, and other structural components. Aluminum sheet plate is also used in the manufacturing of satellites and spacecraft, where its lightweight properties are essential for achieving escape velocity.

Aluminum sheet plate is also used in the marine industry for boat hulls, decks, and other structural components. Its corrosion resistance is especially important in saltwater environments. Aluminum sheet plate is also used in the manufacturing of marine equipment such as winches, masts, and rigging.

In the electronics industry, aluminum sheet plate is used in the production of casings for smartphones, laptops, and other electronic devices. Its lightweight properties make it an ideal choice for portable electronics. Aluminum sheet plate is also used in the manufacturing of heat sinks and other components that require efficient heat dissipation.

In the food and beverage industry, aluminum sheet plate is used in the production of packaging materials such as cans and containers. Its corrosion resistance helps to preserve the freshness of food and beverages. Aluminum sheet plate is also used in the manufacturing of kitchen appliances, cookware, and other items that require a durable and hygienic material.

Overall, aluminum sheet plate is a versatile and durable material that is used in a wide range of industries for various applications. Its lightweight yet strong properties make it an ideal choice for construction, automotive, aerospace, marine, electronics, and food and beverage industries. With its corrosion resistance and high strength-to-weight ratio, aluminum sheet plate is a valuable material that continues to find new and innovative uses in the modern world.

- Benefits of Using Aluminum Sheet Plate for Construction and Manufacturing

Aluminum sheet plate is a versatile and durable material that has a wide range of uses in construction and manufacturing. This article will explore the many benefits of using aluminum sheet plate in these industries.

One of the primary advantages of aluminum sheet plate is its strength-to-weight ratio. Aluminum is a lightweight material, making it easy to transport and work with on construction sites. However, despite its light weight, aluminum is incredibly strong and durable, making it an excellent choice for a wide range of applications, from roofing to structural components.

Another key benefit of aluminum sheet plate is its corrosion resistance. Unlike other metals, such as steel, aluminum does not rust when exposed to moisture. This makes it ideal for use in construction projects where the material is likely to come into contact with water or other corrosive substances. Additionally, aluminum is non-toxic, making it safe for use in a variety of applications, including food and beverage packaging.

In addition to its strength and corrosion resistance, aluminum sheet plate is also highly recyclable. Aluminum is one of the most recycled materials in the world, with nearly 75% of all aluminum ever produced still in use today. This makes aluminum an environmentally friendly choice for construction and manufacturing projects, as it can be recycled and reused indefinitely without losing its strength or quality.

Aluminum sheet plate is also a versatile material that can be easily shaped and formed to meet the specific requirements of a project. Whether it's being used for roofing, siding, or structural components, aluminum can be cut, drilled, and welded to create custom pieces that fit perfectly into a design. This flexibility makes aluminum sheet plate a popular choice for architects and designers looking to create unique and innovative structures.

Overall, aluminum sheet plate is a versatile and durable material that offers a wide range of benefits for construction and manufacturing projects. From its strength-to-weight ratio to its corrosion resistance and recyclability, aluminum is a material that is both practical and sustainable. By choosing aluminum sheet plate for your next project, you can enjoy all of these benefits and more.

- Innovations and Advancements in Aluminum Sheet Plate Technology

Aluminum sheet plate is a versatile and durable material that has seen continuous innovations and advancements in technology over the years. From its humble beginnings as a lightweight metal used primarily for packaging and kitchenware, aluminum sheet plate has evolved into a high-performance material with a wide range of applications in various industries.

One of the key innovations in aluminum sheet plate technology is the development of new alloys that offer enhanced strength, durability, and formability. These alloys have allowed manufacturers to create aluminum sheet plates that can withstand high temperatures, corrosive environments, and heavy loads, making them ideal for use in aerospace, automotive, and construction industries.

Advancements in manufacturing processes have also played a crucial role in improving the quality and performance of aluminum sheet plates. Modern techniques such as hot rolling, cold rolling, and annealing have enabled manufacturers to produce aluminum sheet plates with precise dimensions, smooth surfaces, and consistent mechanical properties.

In addition to their mechanical properties, aluminum sheet plates are also known for their aesthetic appeal and versatility in design. They can be easily formed, cut, and welded to create complex shapes and structures, making them ideal for architectural cladding, signage, and decorative applications.

One of the key advantages of aluminum sheet plate is its lightweight nature, which makes it an ideal choice for applications where weight savings are critical, such as in the transportation industry. Aluminum sheet plates are commonly used in the manufacturing of automobiles, trains, and aircraft, where their high strength-to-weight ratio helps to improve fuel efficiency and performance.

Another important application of aluminum sheet plate is in the construction industry, where it is used for roofing, siding, and structural components. Aluminum sheet plates offer excellent corrosion resistance and durability, making them a cost-effective and low-maintenance solution for building exteriors.

In conclusion, aluminum sheet plate is a versatile and durable material that continues to be at the forefront of innovation and advancement in technology. With its unique combination of strength, lightweight, and formability, aluminum sheet plates are an indispensable material in a wide range of industries. Whether used in aerospace, automotive, construction, or decorative applications, aluminum sheet plates offer unmatched performance and versatility for today's rapidly evolving world.

- Sustainability and Environmental Impact of Aluminum Sheet Plate Production

Aluminum sheet plate is a versatile and durable material that is widely used in various industries for its many applications. From aerospace to automotive, construction to packaging, aluminum sheet plate plays a crucial role in modern manufacturing processes. However, with the increasing focus on sustainability and environmental impact, it is important to explore the implications of aluminum sheet plate production.

The production of aluminum sheet plate involves several stages, starting with the extraction of bauxite ore and ending with the finished product. The mining of bauxite ore can have significant environmental consequences, including habitat destruction and water pollution. In addition, the extraction and processing of aluminum require large amounts of energy, contributing to greenhouse gas emissions and climate change.

To address these environmental concerns, many aluminum producers are implementing sustainable practices in their operations. This includes using renewable energy sources, such as hydroelectric or solar power, to reduce the carbon footprint of aluminum production. Additionally, advances in technology have helped to improve energy efficiency and recycling rates in the aluminum industry.

One of the key benefits of aluminum sheet plate is its recyclability. Aluminum is infinitely recyclable, meaning it can be melted down and reused without any loss of quality. This not only reduces the demand for virgin aluminum ore but also saves energy and resources in the production process. As a result, recycling aluminum sheet plate is a key step towards a more sustainable and circular economy.

In terms of environmental impact, aluminum sheet plate production also has advantages over other materials. Aluminum is lightweight, strong, and corrosion-resistant, making it a preferred choice for applications where durability and longevity are important. Its excellent thermal and electrical conductivity properties also make it ideal for use in various industries, from electronics to transportation.

Overall, aluminum sheet plate is a versatile and sustainable material that offers a wide range of benefits for both manufacturers and consumers. By adopting best practices in production and recycling, the environmental impact of aluminum sheet plate can be minimized. As we continue to explore the many uses of aluminum sheet plate, it is essential to prioritize sustainability and environmental responsibility in the manufacturing process.

Conclusion

In conclusion, aluminum sheet plate is truly a versatile and durable material that can be utilized in a wide range of applications. From construction and automotive industries to aerospace and marine projects, the uses of aluminum sheet plate are virtually limitless. Its lightweight yet strong properties make it a preferred choice for many professionals in various fields. Whether you are looking for a material to enhance the efficiency of your project or simply seeking a durable solution, aluminum sheet plate is definitely worth considering. Its adaptability and resilience make it a smart investment for any project, big or small. So, next time you are in need of a material that can deliver on both performance and durability, look no further than aluminum sheet plate.