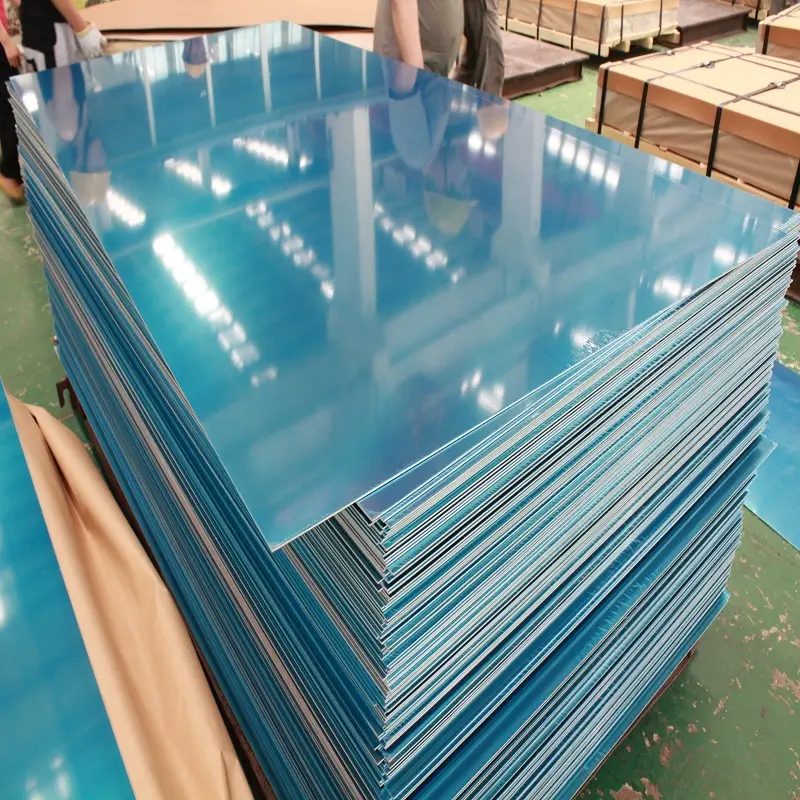

Exploring The Benefits Of Using Aluminium Metal Plates In Industrial Applications

Are you curious about how aluminium metal plates can revolutionize industrial applications? Look no further, as we delve into the numerous benefits of using aluminium in various industries. From its lightweight properties to corrosion resistance, discover how this versatile material can enhance efficiency and durability in your operations. Join us on this exploration of the advantages of incorporating aluminium metal plates in industrial settings.

- Advantages of Aluminium Metal Plates in Industrial Settings

In the world of industrial applications, the choice of materials used can have a significant impact on the efficiency, durability, and overall performance of the project. One material that has gained popularity in recent years is aluminium metal plates. These versatile plates offer a range of advantages that make them a preferred choice for various industrial settings.

One of the key advantages of using aluminium metal plates in industrial applications is their lightweight nature. Despite being incredibly strong and durable, aluminium is significantly lighter than other metals such as steel. This makes it easier to handle and transport, reducing the overall labor costs associated with a project. Additionally, the lightweight nature of aluminium metal plates can also lead to improved fuel efficiency when transporting finished products, further reducing costs for industrial manufacturers.

Another advantage of aluminium metal plates is their excellent corrosion resistance. Aluminium naturally forms a protective oxide layer when exposed to air, which helps prevent rust and corrosion. This makes aluminium metal plates an ideal choice for industrial applications where the plates will be exposed to harsh environmental conditions or corrosive substances. The corrosion resistance of aluminium metal plates results in a longer lifespan for the materials, ultimately saving companies money on costly replacements and repairs.

In addition to their lightweight nature and corrosion resistance, aluminium metal plates also offer superior conductivity. Aluminium is an excellent conductor of electricity and heat, making it an ideal material for applications where heat transfer or electrical conductivity is required. This makes aluminium metal plates suitable for a wide range of industrial settings, from aerospace to electronics manufacturing. The high conductivity of aluminium can also lead to increased energy efficiency in a project, further reducing operational costs for industrial companies.

Furthermore, aluminium metal plates are highly recyclable. Aluminium is one of the most recyclable materials on the planet, with nearly 75% of all aluminium ever produced still in use today. This makes aluminium a sustainable choice for industrial applications, as companies can reduce their environmental impact by using recycled aluminium metal plates. Additionally, the recyclability of aluminium means that companies can save money on raw materials, further reducing the overall cost of a project.

In conclusion, the advantages of using aluminium metal plates in industrial applications are clear. From their lightweight nature to their excellent corrosion resistance, aluminium metal plates offer a range of benefits that make them a preferred choice for a wide range of industrial settings. With their superior conductivity and recyclability, aluminium metal plates are not only cost-effective but also environmentally friendly. Industrial companies looking to improve efficiency, durability, and performance in their projects should consider incorporating aluminium metal plates into their processes.

- Durability and Longevity of Aluminium Metal Plates

Aluminium metal plates have become a popular choice in various industrial applications due to their durability and longevity. These plates are known for their high strength-to-weight ratio, corrosion resistance, and versatility, making them an ideal material for a wide range of industrial uses.

One of the key benefits of using aluminium metal plates in industrial applications is their durability. These plates are known for their ability to withstand harsh environmental conditions, including extreme temperatures, moisture, and chemicals. This durability ensures that the plates can maintain their structural integrity and performance over an extended period, making them a cost-effective option for industrial applications.

In addition to their durability, aluminium metal plates also offer exceptional longevity. Unlike other materials that may degrade or corrode over time, aluminium plates are known for their long-lasting performance. This longevity is attributed to the metal's natural ability to form a protective oxide layer on its surface, which helps to prevent corrosion and deterioration.

Furthermore, aluminium metal plates are lightweight, yet incredibly strong. This combination of strength and lightweight design makes these plates easy to handle and install in various industrial settings. Whether they are used as structural components, protective barriers, or decorative elements, aluminium plates offer a high level of performance without adding unnecessary weight to the overall structure.

Moreover, aluminium metal plates are highly versatile and customizable. They can be easily fabricated and shaped to meet specific design requirements, making them suitable for a wide range of industrial applications. Whether they are being used in aerospace, automotive, construction, or marine industries, aluminium plates can be tailored to fit the unique needs of each project.

Overall, the benefits of using aluminium metal plates in industrial applications are clear. Their durability, longevity, strength-to-weight ratio, and versatility make them a valuable material for a wide range of industries. As technology continues to advance, the demand for aluminium plates is expected to grow, further solidifying their position as a top choice for industrial applications.

- Cost-Effectiveness and Efficiency of Using Aluminium Metal Plates

Aluminium metal plates are becoming increasingly popular in industrial applications due to their cost-effectiveness and efficiency. In this article, we will explore the benefits of using aluminium metal plates in various industrial settings.

One of the key advantages of aluminium metal plates is their affordability. Compared to other materials such as steel or copper, aluminium is much more cost-effective. This makes it an attractive option for companies looking to save money on materials without sacrificing quality. In addition, aluminium is a lightweight material, which can also help reduce shipping and handling costs.

Furthermore, aluminium metal plates are highly durable and resistant to corrosion. This makes them an ideal choice for applications where the plates will be exposed to harsh environments or chemicals. Unlike other materials, aluminium does not rust or degrade over time, ensuring a longer lifespan for the plates.

In addition to their durability, aluminium metal plates are also highly versatile. They can be easily shaped and molded into different designs, making them suitable for a wide range of applications. Whether it's for architectural purposes, automotive components, or industrial machinery, aluminium plates can be customized to meet the specific needs of any project.

Another benefit of using aluminium metal plates is their energy efficiency. Aluminium is a highly conductive material, which means it can quickly and efficiently transfer heat and electricity. This makes it an excellent choice for applications where thermal management is crucial, such as heat sinks or electrical components.

Overall, the cost-effectiveness and efficiency of using aluminium metal plates make them an attractive option for a wide range of industrial applications. Companies can save money on materials, while also benefiting from the durability, versatility, and energy efficiency of aluminium. Whether it's for structural purposes, decorative elements, or functional components, aluminium plates offer a reliable and high-quality solution for any project.

- Versatility and Customization Options with Aluminium Metal Plates

Aluminium metal plates are widely used in various industrial applications due to their versatility and customization options. These plates offer a range of benefits that make them a popular choice for a variety of industries.

One of the key advantages of aluminium metal plates is their versatility. These plates can be easily customized to fit specific project requirements, making them ideal for a wide range of applications. Whether you need a lightweight material for aerospace applications or a durable option for construction projects, aluminium metal plates can be tailored to meet your needs.

In addition to their versatility, aluminium metal plates also offer a high level of customization options. These plates can be cut, shaped, and painted to create a finished product that meets the exact specifications of a project. This level of customization allows for greater flexibility in design and can help to reduce costs associated with fabrication.

Furthermore, aluminium metal plates are highly durable and resistant to corrosion, making them a reliable choice for industrial applications. These plates can withstand harsh environments and extreme weather conditions, ensuring that they will last for years to come. This durability also makes aluminium metal plates a sustainable choice, as they can be reused and recycled for future projects.

In conclusion, the benefits of using aluminium metal plates in industrial applications are clear. These plates offer a high level of versatility and customization options, making them an ideal choice for a wide range of projects. Their durability and resistance to corrosion also make them a reliable and sustainable option for industrial applications. Whether you need a lightweight material for aerospace applications or a durable option for construction projects, aluminium metal plates are sure to meet your needs.

- Environmental Benefits of Choosing Aluminium Metal Plates

Aluminium metal plates have long been a popular choice in industrial applications due to their numerous benefits. One of the key advantages of using aluminium metal plates is their positive impact on the environment. In this article, we will explore the environmental benefits of choosing aluminium metal plates over other materials.

Aluminium is a highly sustainable material, as it can be completely recycled without losing any of its original properties. In fact, aluminium is one of the most recycled materials in the world, with nearly 75% of all aluminium ever produced still in use today. This means that choosing aluminium metal plates over other materials can significantly reduce the amount of waste that ends up in landfills, helping to conserve natural resources and reduce carbon emissions.

Furthermore, the production of aluminium metal plates requires much less energy compared to other materials like steel. Aluminium can be extracted from bauxite ore using a process called electrolysis, which consumes a fraction of the energy required to produce steel. This lower energy consumption translates to lower greenhouse gas emissions, making aluminium a more environmentally friendly choice for industrial applications.

In addition to being energy efficient, aluminium metal plates are also highly durable and long-lasting. This means that they require less frequent replacements and maintenance compared to other materials, further reducing the environmental impact of their use. The longevity of aluminium metal plates can help industries save both time and resources in the long run, while also reducing the amount of waste generated during the lifecycle of the product.

Another environmental benefit of choosing aluminium metal plates is their lightweight nature. Aluminium is significantly lighter than other materials like steel, which means that less fuel is required to transport and install aluminium products. This can lead to lower carbon emissions and reduced environmental impact throughout the entire supply chain.

Overall, the environmental benefits of choosing aluminium metal plates in industrial applications are clear. From its high recyclability and low energy consumption to its lightweight and durable nature, aluminium is a sustainable choice that can help industries reduce their carbon footprint and contribute to a greener future. By opting for aluminium metal plates, businesses can not only improve the efficiency and performance of their operations but also demonstrate a commitment to environmental responsibility.

Conclusion

In conclusion, the use of aluminium metal plates in industrial applications offers a wide range of benefits that cannot be overlooked. From its lightweight and durable nature to its resistance to corrosion, heat, and stress, aluminium metal plates certainly prove to be a valuable material for various industrial needs. Additionally, its versatility in terms of fabrication processes, such as cutting, bending, and welding, further enhance its utility in creating custom solutions for specific applications. As industries continue to evolve and demand more efficient, cost-effective, and sustainable solutions, it is certain that aluminium metal plates will play a crucial role in meeting these requirements. Embracing the use of aluminium metal plates in industrial settings not only ensures enhanced performance and longevity but also contributes to a greener and more sustainable future for all.